Electric car batteries are a critical component of electric vehicles (EVs) that provide the necessary power to propel the automobile.

These batteries are designed to be lightweight and efficient and can hold large amounts of energy. They provide the electrical energy required for the car’s electric motor, offering a clean and sustainable alternative to traditional internal combustion engines. Though several types of batteries are used in electric cars, the lithium-ion battery is the most commonly used.

Lithium-ion batteries have become the mainstay in the electric vehicle industry due to their high energy density, longer lifespan, and ability to deliver consistent power. These batteries comprise various components that work together for optimum functionality and performance. The constituents of a lithium-ion battery include the cathode, anode, separator, electrolyte, and current collectors. Take inventory of their composition and their significance in the world of electric mobility.

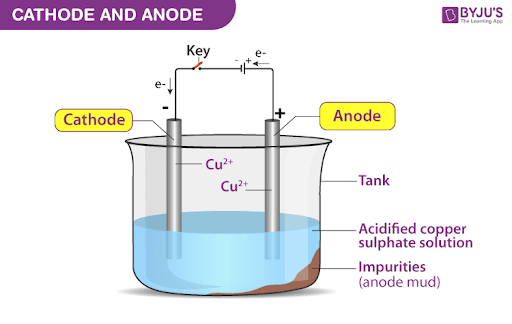

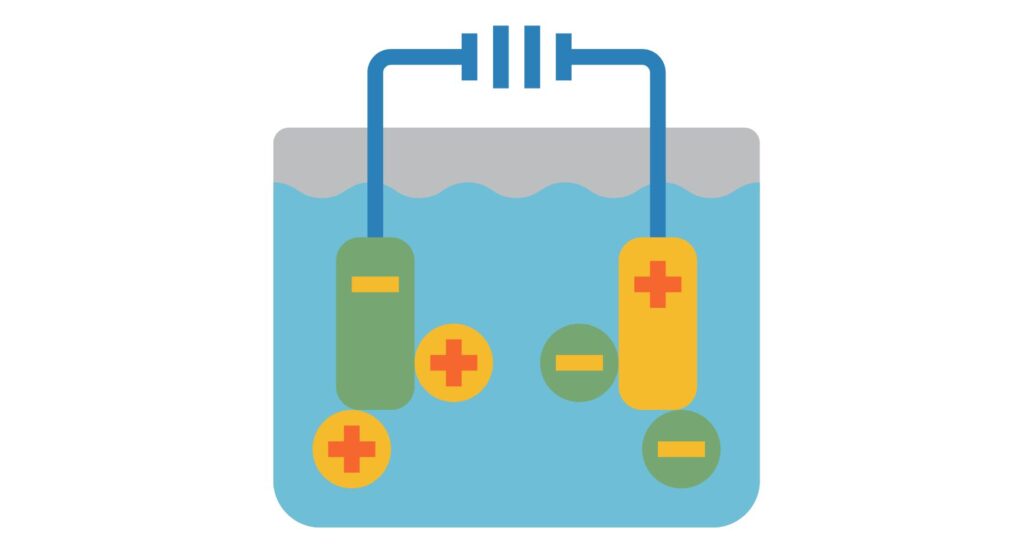

The electrodes are the core components responsible for storing and releasing electrical energy. Lithium-ion batteries have two types of electrodes—a cathode (positive electrode) and an anode (negative electrode).

Cathode: Lithium-based compounds, such as lithium cobalt oxide (LiCoO2), lithium nickel manganese cobalt oxide (LiNiMnCoO2), or lithium iron phosphate (LiFePO4) make up the cathode. The cathode regulates the flow of positively charged ions during the charging and discharging processes. As a result, these compounds offer high energy density, which allows the battery to store more energy.

Anode: Graphite or other carbon-based materials constitute the anode. Graphite can intercalate (absorb and release) lithium ions between its layers during charging to store energy. Thus, anodes, the counterpart of cathodes, facilitates the movement of negatively charged ions.

Electrolyte: The electrolyte facilitates the transport of lithium ions while providing electrical insulation between the cathode and the anode. It is a liquid or gel-like substance containing lithium salts, such as lithium hexafluorophosphate (LiPF6), dissolved in an organic solvent. Thus, electrolyte being a critical component in electric car batteries helps maintain their optimal performance.

Separator: To prevent direct contact between a cathode and an anode, a separator is placed between them.

It is a porous material that works as a physical barrier preventing direct contact and short circuits between the two electrodes. The separator allows the movement of lithium ions while blocking the flow of electrons, maintaining the integrity of the battery. Made of micro-porous materials such as polyethylene or polypropylene, separators provide sufficient ionic conductivity while maintaining electrical insulation.

Current Collectors:

Current collectors are conductive materials that collect and distribute the flow of electrons between the battery electrodes and the external circuit. Typically made of metal foils, such as aluminum for the cathode and copper for the anode, current collectors conduct the flow of electrons in and out of the battery.

In addition to these primary components, electric car batteries incorporate other materials and features to enhance their performance, safety, and durability. For instance, they may include additives in the electrolyte to improve battery stability, enhance cycling performance, and reduce the risk of thermal runaway. Known as Housing and Thermal Management. Battery management systems (BMS) also monitor and control the battery temperature, voltage, current, and state of charge.

Therefore, these components enable the lithium-ion battery to store more energy in smaller and lighter packages. Hence, this is crucial for the electric vehicle’s range and performance.

One cannot overstate the significance of lithium-ion batteries in the electric mobility domain. Their high energy density allows electric vehicles to travel long distances on a single charge, alleviating concerns about range anxiety. Moreover, their relatively longer lifespan means a lithium-ion battery can endure several thousand charge-discharge cycles. This durability contributes to the overall longevity and economic viability of electric cars. As battery technology advances, its costs decrease, making electric cars more accessible to a broader range of consumers. Furthermore, lithium-ion batteries are more environmentally friendly. It accelerates the adoption of electric vehicles and contributes toward reducing greenhouse gas emissions and dependence on fossil fuels.

Overall, the combination and design of these components determine the performance, energy density, and lifespan of electric car batteries. Extensive research and development efforts continue to enhance the performance of lithium-ion batteries further. Researchers are exploring alternative battery chemistry and materials like lithium-rich layered oxides or solid-state batteries. These advancements have the potential to revolutionize electric car batteries and make them even more efficient, affordable, and environmentally friendly.

Conclusion

The main component of electric car batteries is the lithium-ion battery that powers electric vehicles. Their design and composition involve electrodes, electrolytes, separators, and current collectors. Their development has advanced electric mobility, making electric cars more practical, affordable, and sustainable. Therefore, switching to electric vehicles means driving the transition toward a cleaner and more efficient transportation system.

Related Blog:- Power and Efficiency: Discover the Best Electric Cars in India

FAQ’s

What type of battery is used in an electric car?

Electric cars commonly use rechargeable lithium-ion batteries due to their high energy density, longer lifespan, and durability.

What are the main components of electric car batteries?

The main components of lithium-ion batteries are the cathode, anode, separator, electrolyte, and current collectors.

Why are lithium-ion batteries widely used in electric cars?

Lithium-ion batteries have become the preferred choice for electric cars due to their high energy density, long life cycles, and relatively low weight. These enable electric vehicles to operate without relying on internal combustion engines.